PRODUCTS

AG-1800 Aerosol Generator

Description

product introduction

AG-1800 aerosol generator is our company independent research and development only rely on the principle of heating to produce and output aerosol particles of aerosol generator.

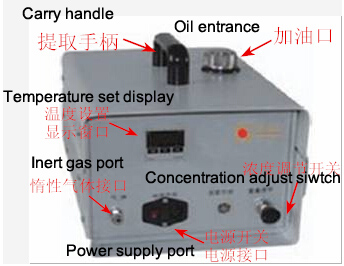

Parts description:

Nozzle connector:

3.) Operation:

① Open the scale at the top of the generator, add the required liquid medium until the scale shows the maximum scale of 3/4.

When the liquid medium is placed, do not exceed the maximum capacity of the generator, otherwise it will not work properly.

②.Connect the standard 1/4 "outer diameter plastic tube from the inert gas inlet, in front of the generator box, adjust the pressure of the compressed inert gas source.

In order to avoid the fire, inert gas must use the following: the most commonly used is nitrogen, carbon dioxide and argon.

Do not use compressed air.

③ Connect the power cord to the appropriate voltage, and then turn on the switch.

④ Adjust the pressure regulator so that the pressure of the inert gas source to 50 psig, and keep this pressure.

Increasing or decreasing the inertial pressure greater than or less than 50 psig will affect the aerosol output of the aerosol generator.

⑤ When the temperature of the temperature controller reaches the specified operating temperature (approximately 20 minutes), the generator is ready to produce particles.

When the generator starts to occur, the temperature will decrease, this is normal.

⑥. Adjust the control valve located in front of the operator panel before opening the switch. The regulator is used to adjust the aerosol concentration. Counterclockwise adjustment will increase the concentration of aerosols, on the contrary will reduce the concentration of aerosols. When using the generator for the first time, adjust the valve to the maximum, when the inert gas began to enter, you can achieve the output requirements.

When the green indicator light is on, it indicates that the temperature has reached the required level (temperature requirement 765 ° F +/- 10). When the concentration control valve is set to the maximum concentration, the aerosol will occur for 3 hours. The aerosol will be stably ejected from the nozzle of the generator in the form of white smoke. When the concentration control valve to the maximum concentration

At the same time, all the aerosol output was diluted by 6,500 cfm of gas. The concentration of aerosols will reach about 100ug / l.

⑦ When the test is completed, adjust the pressure regulator clockwise until the generator stops working. This can purify the internal heating module.

⑧ To determine that all aerosols have finished, wait about 30 seconds after the regulator has been closed.

⑨ At last turn off the generator power.

Please confirm the following before transporting the generator:

A. Make sure the concentration control valve is fully closed. (To clockwise can not move)

B. Make sure that the generator's switch is off.

C. Open the liquid level at the top of the generator and turn the generator back and drain the generator inside liquid.

D. Put the lip on the liquid level and tighten it.

4.) Technical parameters:

|

Model |

AG-1800 |

|

Available flow range |

1500-65000cfm42-1800m³ / min) |

|

Suspended particles concentration |

10ug / L: air flow 65000cfm (about 1800m ³ / min) |

|

Suspended particles concentration |

100ug/L:air flow :6500cfm(about180m³/min) |

|

The occurrence of particles |

PAO, DOP, polydisperse |

|

Compressed gas (inert) |

Nitrogen, Argon, Carbon, Dioxide or Helium (50psi) |

|

Power supply: |

220V AC,50Hz |

|

Out dimension: |

35 W× 25D ×25 H(cm) |

|

Weight |

9.1kg |

Previous

Previous