PRODUCTS

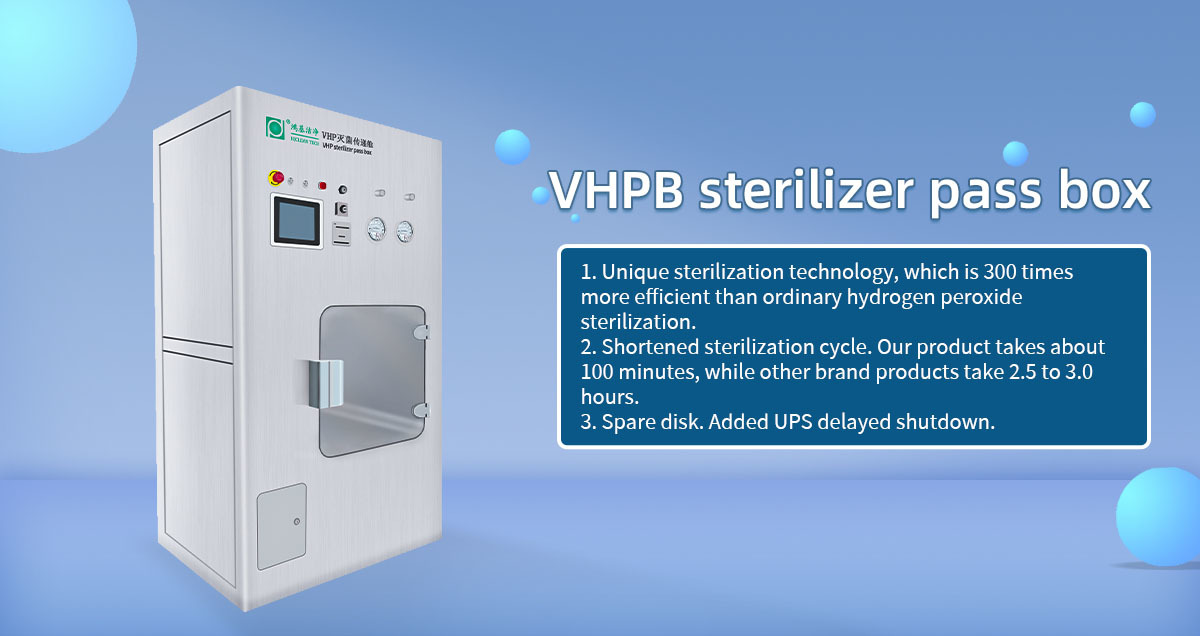

VHP series sterilization pass box

Description

product description

The VHPB series sterilization pass box is a special sterilization equipment that can provide absolute biological decontamination on the surface of the article when transferring articles between different functions. It is equipped with a dedicated hydrogen peroxide VHP generator, a sterile air supply system, an electromagnetic door interlocking system, a closed system, a residue removal system after sterilization, a dedicated HMI (human machine interface) and a sterilizing medium delivery system. It is widely used for surface sterilization at room temperature in places such as pharmacy, medical treatment, sanitation, biological experiment, etc.

Brief description of work process

The working process is divided into five stages: pre-sterilization cabin airtightness detection, system preheating and dehumidification, microbial decontamination and sterilization, residue removal, and Class A laminar flow ventilation.

3.1 Check whether the airtightness of the chamber can meet the sterilization function before sterilization and whether the airtightness meets the requirements.

System leakage rate detection-inflate the sterilization chamber to make the pressure in the chamber reach the set value, maintain the pressure, and the leakage amount within the set time is not greater than the specified value, indicating that the system is well sealed and can enter the sterilization process.

3.2 Preheating and dehumidification of the system-sending clean and dry air into the cabin to keep the humidity in the cabin at a low value, which is conducive to hydrogen peroxide sterilization.

3.3 Sterilization procedure-input hydrogen peroxide vapor into the sterilization chamber, and maintain the expected concentration of the sterilization chamber, keep the VHP concentration above the set concentration, and maintain the sterilization time for more than 30-60 minutes (chemical test paper and biological Test paper verification);

3.4 Residue removal-stop the input of hydrogen peroxide vapor, switch the sterilization system to the residue removal system, so that the hydrogen peroxide gas in the sterilization chamber circulates through the catalyst for decomposition, quickly reduces the hydrogen peroxide concentration, and then ventilates to achieve Hydrogen peroxide remains below 1PPM.

3.5 Class A laminar flow-the air supply fan is turned on, and the fresh air valve and exhaust valve are adjusted to keep the pressure difference between the cabin and the high-level cabin greater than 10Pa. The air flow can be horizontal unidirectional flow or vertical unidirectional flow. After the sterilization and removal of residues are completed, the cabin maintains a laminar flow state. After the high-level side door is opened, the cabin is still in a laminar flow air supply state.

The main parameters

Material: External 304 stainless steel, internal cavity: 316L stainless steel

Cleanliness class CLASS A

Leakage rate ≤0.5%VOL/h (under 100Pa)

Air change ≧80T/h

Vaporization temperature ≤60℃

Compressed air ≥0.5Mpa

Sterilizer better than 30% food grade hydrogen peroxide solution

VHP residue removal efficiency ≤1PPM

Control method manual or automatic

Noise ≤70dB(A)

main feature

● Automatic leak detection:

Inflate the cabin and check whether the system remains airtight. If the airtight requirements are met, then enter the sterilization process. If the airtight requirements are not met, continue to inflate and airtight, and then leak detection, and so on until the airtight conditions are met.

● Efficient flash evaporation method:

The hydrogen peroxide solution is atomized and then flashed at low temperature to become hydrogen peroxide vapor, the hydrogen peroxide will not be decomposed due to the flashing, and the hydrogen peroxide evaporation process is highly efficient.

● Quickly remove residue:

High-efficiency hydrogen peroxide remover, in addition to residues quickly and completely, no external discharge is required.

● Sterilization process record:

Automatically detect the sterilization concentration and automatically draw the sterilization process curve.

● Door interlock function:

The two doors of the equipment cannot be opened in the state of leak detection, sterilization, and residue removal. The high cleanliness level side door can only be opened after the residue removal reaches a safe concentration. The two doors cannot be opened at the same time.

● Antibacterial treatment on the surface of the cabin:

The surface of the inner cabin adopts special treatment, which can achieve the effects of sterilization and antibacterial, so that the surface of the inner cabin will never have a habitat for microorganisms.

● Comply with computerized verification software:

The system has audit trail and electronic signature functions.

Previous