PRODUCTS

Y09-6S

Description

1. Purpose

The Y09-6S laser dust particle remote sensor (hereinafter referred to as the sensor) is used to measure the size and number of dust particles in a unit volume of air in a clean environment, and the number of corresponding particles is communicated with the upper computer through RS485 communication, and the upper computer can control the sensor To proceed. It can monitor the clean environment with cleanliness levels ranging from one hundred thousand to one hundred.

This sensor uses semiconductor laser light source, small size, light weight, high monitoring accuracy, computer operation, and very convenient to monitor clean environment. It is widely used in electronics, optics, chemistry, food, cosmetics, medicine and health, biological products, aerospace and other sectors.

2. Main technical parameters

1. Dimensions 95*160*45 or 168*105*45mm3 (width × height × thickness)

2. The mass is about 0.8 or 1.8kg

3. Maximum power consumption 8VA

4. The power supply is externally connected to 7.5-12VDC/2A, 9V is recommended

5. The upper computer particle size channel is 0.5, 5.0µm, 0.3µm optional

6. Sampling flow 2.83L/min

7. Sampling period 1-40 minutes optional, standard 1 minute

8. Use environment temperature: 10℃——30℃

Humidity: 20%-75%

Ambient pressure and sampled gas pressure: 86kPa-106kPa

9. The maximum allowable sampling concentration is 35,000 particles/L (the particle size of the dust particles is not greater than 0.5 µm), and the sampling air must not contain corrosive gases such as acid and alkali

10. Self-cleaning time≤10min

3.working principle and function

This sensor adopts the principle of light scattering. When suspended particles in the air pass through the photosensitive area, they scatter light flux proportional to their particle size. After photoelectric conversion, amplification and processing, the equivalent diameter and number of collected particles are obtained.

4.use operation steps

1. Installation: Fix the sensor and the constant velocity sampling head according to the requirements of the relevant detection and installation points, and connect the sampling port and the constant velocity sampling head with a randomly configured hose.

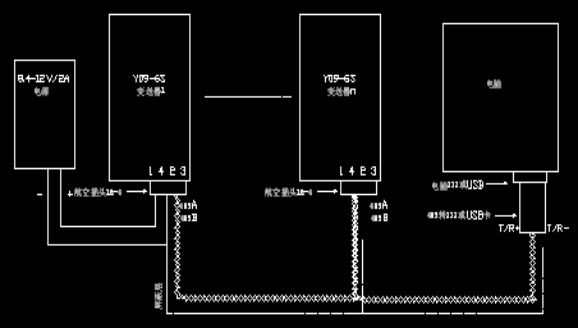

2. Wiring: It is recommended to use a 2-core shielded or twisted pair for the RS485 signal line, of which 2-core is used for signal transmission and reception, and one end of the shielding layer is connected to the input power 0V and the other end is used as the signal neutral line. All wire diameters are available between 0.35-1.0. As shown below. The pin definition of the 16-4 interface of the aviation plug on the sensor side: 1 pin (red) power positive input 2 pin (green) 485A 3 pin (blue) 485B 4 pin (black) 0V. Computer terminal 485 to 232 or USB card wiring definition: sensor terminal 2 feet connected to T/R+ 3 feet connected to T/R- shielded wire can not be connected. After the wiring is correct, power on and turn on the sensor power switch.

3. Run the host computer monitoring software and select the COM port. Operate by software.

5.maintenance and troubleshooting

1. Precautions for the use and storage of the instrument

⑴. The working position of the instrument and the sampling port should be under the same air pressure and the same temperature and humidity environment to ensure the normal operation of the instrument and avoid condensation and damage to the instrument.

⑵. It is forbidden to extract gas containing water vapor, oil, corrosive substances and high temperature gas, and it is forbidden to use it in an environment with high dust concentration and large particles to avoid damage to the sensor. Cover the protective cover of the sampling port when disinfecting in the workshop to avoid oxidizing the laser and glass lens inside the sensor.

⑶. The power switch and external power supply should be turned off when the instrument is not in use, and the sampling port should be protected.

⑷. When transporting, it should be handled with care to avoid vibration and shock.

⑸. The instrument is allowed to be transported and stored in the following environment for short-term storage in the state of factory packaging:

Temperature: -40℃——50℃

Humidity: 90%RH(40℃)

Previous

Previous