PRODUCTS

VHP generator/ VHPS hydrogen peroxide disinfection machine

Description

product description

Vaporized hydrogen peroxide (VHP) sterilizer uses the advantages of hydrogen peroxide in its gaseous state at room temperature to have more spore-killing ability. After generating free -OH, it is used to attack cell components, including lipids, proteins and DNA. A technology that meets the requirements of complete sterilization. It is often used for the sterilization of enclosed spaces such as isolation rooms and isolators.

working principle

Vaporized hydrogen peroxide sterilization uses the advantages of hydrogen peroxide that has more spore-killing ability in a gas state than a liquid state at room temperature, and vaporizes liquid H2O2 and quickly generates free hydroxyl groups (HO--) for attack Cellular components, including lipids, proteins and DNA tissues, destroy their structure and meet the requirements of complete sterilization. Vaporized hydrogen peroxide sterilizer is to vaporize H2O2 solution with a concentration of 35%, that is, hydrogen peroxide vapor through a vaporizer into hydrogen peroxide vapor, and then through the plasma device to transform the particles into gas HO-, and transport to the space through the pipeline for disinfection and sterilization device of.

Brief description of work process

The biological decontamination process of plasma vaporized hydrogen peroxide sterilizer can be divided into four stages:

1. Vaporization stage: the hydrogen peroxide solution is input into the vaporizer to be vaporized into hydrogen peroxide vapor, and then input to the mixing chamber through a fan for processing;

2. Plasma generation stage: Introduce hydrogen peroxide in the vapor state into the plasma generation chamber, convert the vapor hydrogen peroxide into plasma hydrogen peroxide, and send it to the sterilization chamber;

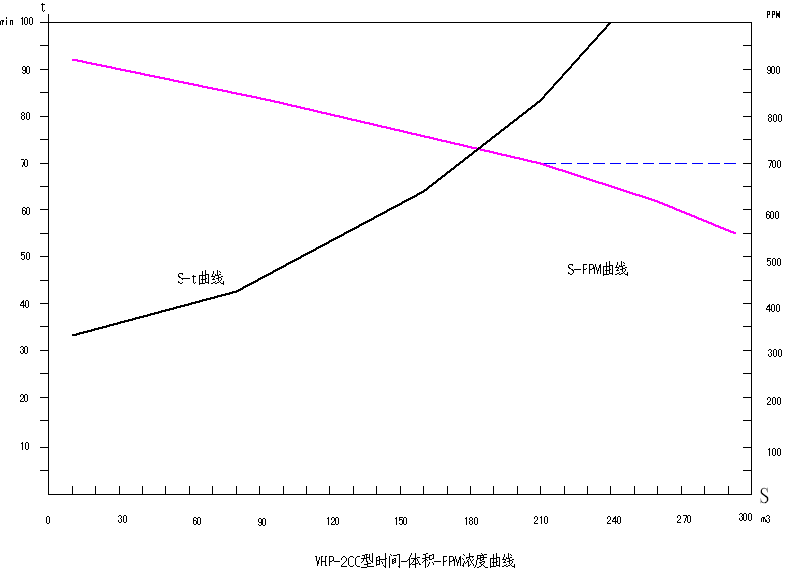

3. Biological decontamination maintenance stage: continue to input hydrogen peroxide plasma into the sterilization chamber until it reaches the preset concentration (usually based on the biological test paper verification concentration value) and start timing, and keep 30~ above the preset concentration 35min, the biological decontamination is completed (the sterilization efficiency of 30min is verified to reach 6-log), and the hydrogen peroxide vaporization and plasmaization are stopped;

4. Residual stage: the gas system is switched to the residual device, the hydrogen peroxide in the vaporized plasma is converted into water and oxygen through the decomposer, and the hydrogen peroxide concentration in the air is continuously circulated to reduce the concentration of hydrogen peroxide in the air to less than 1ppm.

The operation of each stage can be individually controlled manually or automatically, running one by one in order.

Technical characteristics

Large sterilization space, which can quickly and uniformly sterilize VHP in a large space

Color touch screen display, stable and reliable work, intuitive and simple interface

Data saving and printing function, sterilization process curve and sterilization report

Sterilization parameter memory storage function, directly recalled during sterilization

Low temperature sterilization process, just room temperature

Remote control, safe operation

Less residue, hydrogen peroxide decomposes into water vapor and oxygen, no toxic by-products

Spectral sterilization, the ability to kill thermophilic fat spores is 6lg

Performance parameter

Working method: continuous work

Sterilizer: food grade hydrogen peroxide solution (mass concentration ≥30%)

Vaporization temperature: ≤ 40 ℃

Injection rate: 0 ~ 30 g/min

Decontamination ability: the ability to kill thermophilic fat spores is 6lg

Size: 530*700*1300mm

Power: 1.2kw

Sterilization volume: ≤100m³, 200m³, 300m³ optional

Previous

Previous